Physical layer options

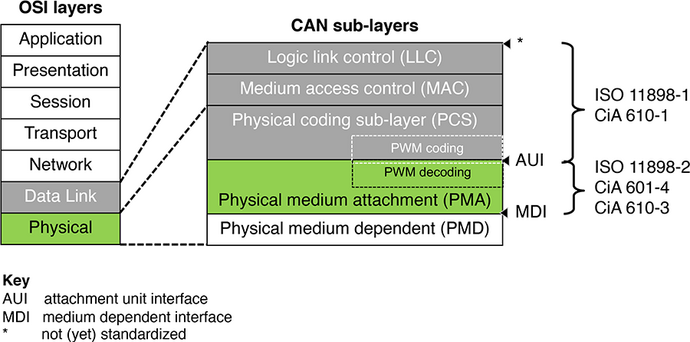

There are several CAN physical media attachment (PMA) sub-layers standardized. They are normally implemented by means of transceivers. Most common is the CAN high-speed transceiver. This includes variants supporting bit-rates up to 1 Mbit/s and those providing tighter symmetry features suitable for higher bit-rates depending on the network design (CAN FD transceiver). The CAN SIC (signal improvement capability) transceiver are able to suppress ringing on the network lines. They are specified in CiA 601-4 and CiA 610-3 (supporting PWM coding/decoding).

Most of the CAN physical layer options use twisted-pair copper cable with common ground usually realizes the physical transmission. Of course, all connected nodes need to support the same bit-rate(s) and the same bit-timing settings.

The physical medium attachment (PMA) options include:

- CAN high-speed transceiver with optional low-power and optional selective wake-up capability (ISO 11898-2:2016)

- CAN SIC (signal improvement capability) transceiver (CiA 601-4)

- CAN XL SIC transceiver (CiA 610-3)

- CAN low-power/fault-tolerant transceiver (ISO 11898-3:2006)

- CAN truck/trailer transceiver (ISO 11992-1)

- Single-wire CAN (SWC) transceiver (SAE J2411) – not more recommended for new designs

Most common is a high-speed transmission up to 1 Mbit/s. This is realized by means of CAN high-speed transceivers (term recommended by CiA). These transceivers are optionally available with low-power capability and selective wake-up functionality for partial networking. They are all standardized in ISO 11898-2:2016. Nowadays, this standard includes the legacy ISO 11898-5 and ISO 11898-6 norms, too.

The robustness of high-speed CAN networks is excellent. In-vehicle networks often use star-topologies, sometimes with multiple stars. In some applications, hybrid topologies are implemented, combining line and star topology elements. However, the most robust topology is a bus-line with very short stubs.

For bit-rates higher than 1 Mbit/s as used in the CAN FD data-phase, the CAN high-speed transceivers with improved symmetry features are used. They are also standardized in ISO 11898-2:2016. There are two versions specified: one with improved parameters suitable for bit-rates up 2 Mbit/s and another one with even better parameters suitable for bit-rates up to 5 Mbit/s. Of course, the achievable bit-rate depends highly on the physical network design. This includes topology, selected cables and connectors, etc. Additionally, CiA has specified the CAN SIC (signal improvement capability) transceivers, which can suppress ringing (CiA 601-4). This gives network designers more margin for asymmetries, which can be caused by not optimized network topologies. The CAN SIC XL transceivers featuring an optional PWM (pulse-width modulation) coding are specified in CiA 610-3. They support bit-rates of up to 10 Mbit/s and more depending on the network topology and selected electromechanical components (e.g. cables, connectors, and additional circuitry).

The other physical layer standard used in the automotive industry is ISO 11898-3, a so-called fault-tolerant, low-power transmission. It is not widely used in other industries, and it is limited to 125 kbit/s. An application-specific physical layer is standardized in ISO 11992-1, which is also limited to 125 kbit/s. It is used in truck-trailer point-to-point networks. The single-wire transmission as specified in SAE J2411 has some restrictions regarding the robustness and the transmission rate. It is not widely implemented.

Other medias are also in use: Fiber-optical and power-line transmissions, for example. However, their specifications are proprietary.