CiA® 436 series: CANopen application profile for construction machines

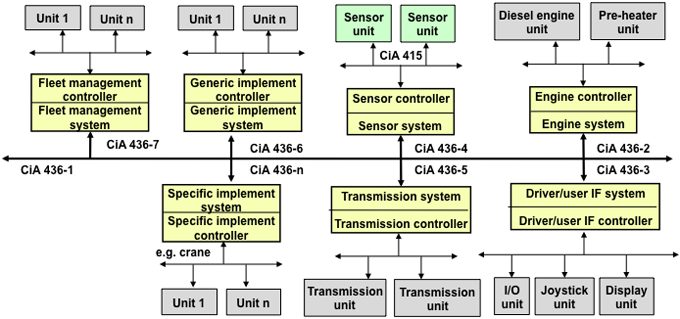

The profile specifies the use of CANopen networks on construction machineries by introducing the virtual control architecture. The latter integrates the interfaces to the (diesel) engine control system, the drivers’ desk, the sensor control system, the transmission control system, the fleet management control system, and the implement (superstructure) control system. CiA 436-1 specifies the integration network with the interfaces to the mentioned sub-systems. For each sub-system a separate application profile is specified (CiA 415 for sensor control) or is in development within further sub-parts of the CiA 436.

The idea for an integration network came from the rail industries. Unfortunately, the construction industries do not use such integration networks yet. Instead, normally the main controller is connected to all the networks. The currently valid CiA 436-1 version 1.1.0 is available since June 2010. The sub-network for sensor control systems is specified in CiA 415. Other CiA 436 parts specifying further sub-networks are in development.

Interested parties are invited to participate in development of further sub-systems.

The general physical layer definitions for CANopen devices (see CiA 301) apply. Compliant devices support bit-rates of 125 kbit/s, 250 kbit/s, and further (optional). The 7-pin connector and the 5-pin micro-style (M12) connector with CiA 106 pinning are recommended for the CANopen network connection. An additionally defined application-specific 8-pin round connector does not comply with CiA 106. CANopen devices implementing this profile support the CANopen status and error LED (see CiA 303-3).

It is recommended that the CANopen NMT manager functionality resides on the device interfacing with the drivers’ desk control system. Other systems provide CANopen NMT slave functionality. The node-ID assignment is manufacturer-specific. For node-ID assignment via CAN (e. g. for IP67-rated devices) the CANopen layer setting services (LSS, see CiA 305) may be used. The heartbeat functionality is used for error control. Additionally to the reaction on a communication error and an internal device error, the reaction on a sub-network failure is configurable. The object 1000h indicates the type of the CANopen device and its functionality e.g. the generic construction machinery controller or the interface to a certain sub-system. This profile provides no PDO definitions, no special redundancy concepts, and no special mechanisms for safety-related data communication. If such functionalities are required, the definitions given in the corresponding documents (respectively CiA 301, CiA 302-6, and EN 50325-5) apply. The general device parameters contain the information about the used machine (type, manufacturer, serial number etc.), fleet management, superstructure (type and serial number), date and time as well as the operating hours.

| Title | Details | Status Size |

Published Action |

|---|---|---|---|

| CiA 301 version 4.2.0CANopen application layer and communication profile | DescriptionThis specification specifies the CANopen application layer. This includes the data types, encoding rules and object dictionary objects as well as the CANopen communication services and protocols. In addition, this specification specifies the CANopen network management services and protocols. This specification specifies the CANopen communication profile, e.g. the physical layer, the predefined communication object identifier connection set, and the content of the Emergency, Timestamp, and Sync communication objects. Keywordsn/a | PAS3.0 MiB | 2011-02-21Login |

| CiA 415 version 2.2.0CANopen application profile for sensor systems in road-construction and earth-moving machines | DescriptionThe CANopen sensor system application profile for road construction and earth moving machines specifies the communication interface for sensors as well as the sensor control unit. The profile is suitable for a broad range of machine types (e.g. paver, compactor, grader, dozer, mill, heater and truck). Keywordsn/a | DSP1.9 MiB | 2009-04-22Login |

| CiA 305 version 3.0.0CANopen layer setting services (LSS) and protocols | DescriptionThis document specifies the layer setting services (LSS) and protocols for CANopen. These services and protocols are used to inquire or to change the settings of three parameters of the physical layer, data link layer, and application layer on a CANopen device with LSS server capability by a CANopen device with LSS manager capability via the CAN network. Keywordsn/a | DSP1.9 MiB | 2013-05-08Login |

| CiA 436-1 version 1.1.0CANopen application profile for construction machines - Part 1: General definitions | DescriptionThis application profile provides general definition as well as recommendations for using CANopen control networks on construction machineries. In addition, this application profile introduces the virtual control architecture on construction machineries, integrating the engine control system, the drivers’ desk, the sensor control system, the transmission control system, the fleet management control system as well as the control system for the superstructure respectively implement. Keywordsn/a | DSP530 KiB | 2010-06-30Login |

| CiA 106 version 1.1.0Connector pin-assignment recommendations | DescriptionThis document recommends the connector pin-assignment for CAN interfaces. This includes the CAN_H and CAN_L pins, the ground pin, and the power supply pins. Keywordsn/a | TR0.9 MiB | 2023-07-11Login |