CAN: From physical layer to application layer and beyond

The CAN knowledge pages provide technical information on all three CAN (Controller Area Network) data link layer generations:

The CAN knowledge pages also describes several CAN physical layer options. Additionally, these pages also contain technical descriptions about classic CANopen and CANopen FD as well as other standardized CAN-based higher-layers.

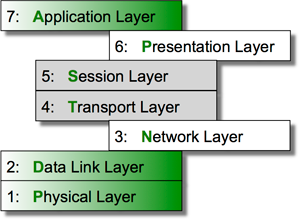

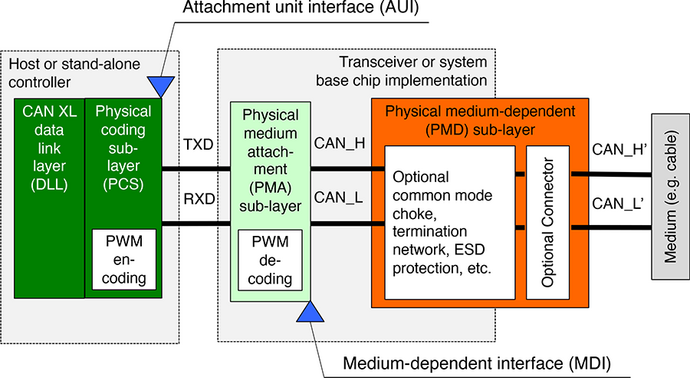

According to the Open System Interconnection (OSI) seven-layer and the CAN lower-layer model, the CAN lower layers cover some functions of the transport layer (e.g. automatic retransmission of faulty frames), the data link layer (DLL), and the physical coding sub-layer (PCS) as well as the physical medium attachment (PMA) sub-layer. The medium-dependent interface sub-layer is generally application-specific.

The other layers are usually referenced as higher-layer protocols (HLP). Often, the CAN-based application layer approaches include functional elements of other higher layers (e.g. session, presentation, transport, or network layers), too. Some of them are accompanied by parameter (data) specifications, which are not in the scope of the OSI model.

Higher-layer protocols described in the CAN knowledge pages include, in particular, the classic CANopen application layer (CiA 301) and the CANopen FD application layer (CiA 1301) as well as the related device, interface, and application profiles. Additionally, some basic information on other CAN-based higher-layer protocols such as Devicenet, Isobus (ISO 11783), ISO 11992 series, and SAE J1939 series) is provided.